Products

From scratch to maturity...

...goes our range of services that have been deployed. Until recently we only had development and consulting as services in this category

Not long since we were able to break ground as a provider for electric control units. Thereby our high competence in algorithm development advanced greatly. Most of our products are based on the safety relevant anti-trap mechanism. Initiated in the automotive industry this also establishes very well in the industrial appliance. In the process we were able to establish ourselves in the drive control for DC-motors.

Air Quality Sensor

Over the last two years we have learned that correct and sufficient ventilation is the only way to get us through the pandemic. The reason for this is the aerosols that are in the air.

Aerosols are solid or liquid particles that float in the air. It is precisely these aerosols which are in exhaled air, that can potentially transmit viruses.

Each person exhales around 8 liters of air per minute that has been in close contact with the lung tissue. The exhaled air therefore contains not only CO2 but also tiny liquid droplets, the

aerosols, which can float in the air for a long time due to their size. If the respective person is infected with the virus, these droplets will contain virus particles.

Considering the aerosol sinking speeds and the decrease in virus infection activity, the air in the room remains polluted for a long time. If a healthy person breathes in too many of these contaminated droplets and reaches a certain viral load, the disease is transmitted.

The timely ventilation of rooms should therefore prevent the aerosol concentration from exceeding a critical value. An optimal room climate does not have a higher CO2 value in indoor air than in

outdoor air.

Therefore, when a threshold value of 800 ppm CO2 is reached, ventilation should be carried out in order to reduce

the concentration back down to 500 ppm.

We have developed the Air Quality Sensor AirQS to ensure that air quality is monitored quickly and easily.

We use it to constantly check the air quality in the room and sound the alarm as soon as a critical CO2 value is reached.

The device can be networked with any electrically height-adjustable office desk and ventilation system, or it simply be used via plug and play, for which only a USB interface is required.

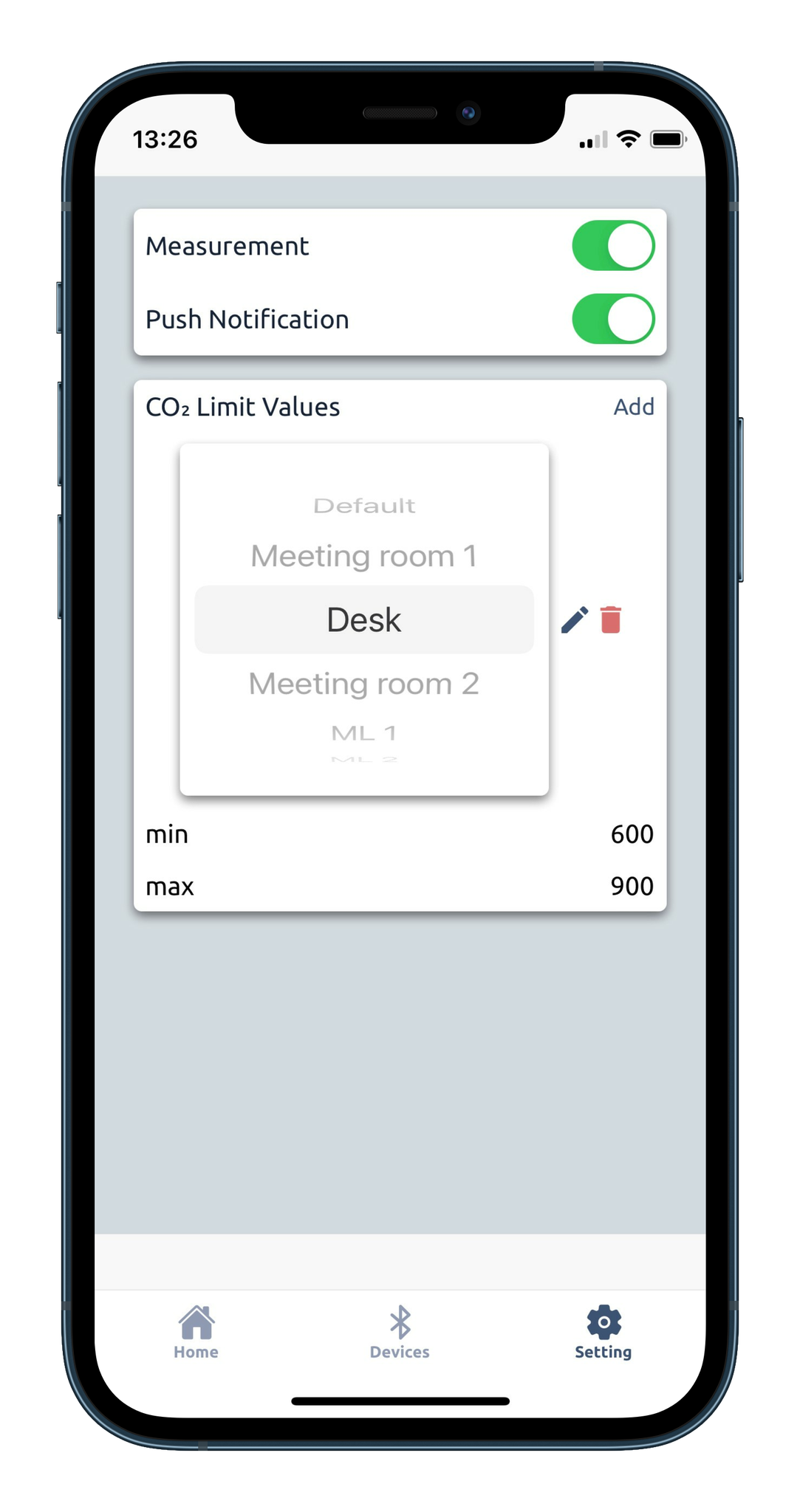

The sensor can be easily controlled via an app. In addition to the pre-set default limits, you can freely parameterize your own limit values. Warning messages are conveniently sent via push

notification. With constant monitoring, alarms are issued if the respective threshold value is exceeded or not reached.

The device has extremely small dimensions of approx. 55 x 40 x 22 mm³ and can therefore be easily attached anywhere.

C.A.S.CO

Our control units have proven themselves over years in use for several hundred thousand electronically controlled sunblind systems. We want to make use of this experience for various other applications.

- Configurable Automotive Semiconductor COntroller

This fully developed control unit is suited perfectly to control DC motors in a LIN environment. Especially in a high load range it works very convincing with fast switching time and precise position information.

You will be perfectly equipped with our complete kit. You only need to connect your DC motor- the desktop app will do the rest. It makes it very easy to determine your ideal system parameters. These parameters are then uploaded into our software with which you can adjust your settings in only a few minutes. This makes it possible for you to work with a perfectly customized solution under minimal effort. You will receive an all-in package from us with all implemented features, ready to use.

We count on semiconductor technology instead of relays. Thus, our control units have several advantages. The device is extremely silent, it has a very precise response behavior and above all absolutely no abrasions or icing can occur. Its high dynamic in the load range and its low power consumption round off the ECU very convincingly. Our excellent quality scores certainly speak for themselves!

Our housing uses a 12-pole FCI connector by default and is manufactured from the material PA6-GF15. On request we gladly offer other housing options. Additionally, a 2-component potting technology on a silicon basis protects the unit from environmental influences.

Another advantage of our ECU is that you as our customer are only facing minimal costs. Due to long-standing economies of scale the ECU has a steady low unit price. You also won’t be facing any development costs as the application becomes an absolute child’s play thanks to our complete kit.

This means that until placing the order no costs will be generated for you as we gladly provide the configuration kit for the duration of the application free of charge (further details on the scope are available on request). Hence it is completely up to you to decide how you want to work with our very intuitive GUI without having to invest preemptively.

You can immediately start with your configuration and define parameters like power threshold, various voltage thresholds, various timeouts, movement and reversion distances, initialization type and many more. Optionally we can offer you an anti-trap system which meets all international standards and requirements.

That way you can get your system ready for series production quickly and efficiently with the help of our complete package.

Smart Motor Control Unit

The control units are perfectly suited for a large range of various lifting system applications. They are individually configurable equipped with a memory function.

The 2-motor model can be connected with up to two actuators which makes it a very good choice for small, individual applications. In comparison the 3-motor model is cascadable with up to three further 3-motor units. This means that it is possible to configure and control up to 12 actuators simultaneously

Our control units ensure a smooth, synchronized movement of the connected drive units. A parametrizable soft-start/stop function completes the high standard driving behavior.

All our control units have an integrated collision protection mechanism. They are compatible with various operating devices. Additionally, they are equipped with a diagnosis capability via an external GUI. The 2-motor unit works with a power of 280W, whereas the 3-motor unit works with 360W.

Moreover, even from an ecological point of view out units are an exceptionally good choice. They show a very low power consumption during standby mode- only 0,1W!

Automotive

One of our showcases is the development and production of ECUs for an electronic shade system.

These control units are then built into vehicles of notable manufacturers. It can be controlled via a dual level switch for manual and automatic run. In doing that the ECU is actuating the DC-Motor voltage-, power- and velocity-monitored and controls the position of the particular system via hall sensors.

The implementation of special block algorithms or the development of task optimized thermal protection allows the exhausting of the mechanical systems for their specific use.

The ECUs were introduced to the EU- and US-market and fulfill all the necessary legislation requirements concerning anti-trap. The control units will be distributed to EMS-partners by our subcontractors.

In addition to the sunshade systems we offer control units for convertible soft-tops. In general, these ECUs are integrated into the vehicle architecture via LIN bus. The actuating can be carried out selectively through bus commands or mechanical switches.

As with the ECUs for the sunshades we too offer the distribution in cooperation with our production partner for the convertible soft-tops.

Control Unit for a Fire Extinguisher

The control unit of the electrical Fire Extinguisher is able to deplete up to two independent fire protection systems simultaneously. Immediately after starting the ECU an automatic self-test is conducted. This can also be done anytime via user request during on-mode. Feedback follows via an optical signal. The integrity checks are triggerable at any time by the driver and / or a safety marshall.

The device is designed after the standards FIA 8865-2015 and EN-60529-2014 and is thus ideally usable for motorsports.

The housing is constructed very robust so it can withstand a high mechanical strain and protect the ECU from any outside influence. A very reliable functionality is guaranteed.

Motorsports